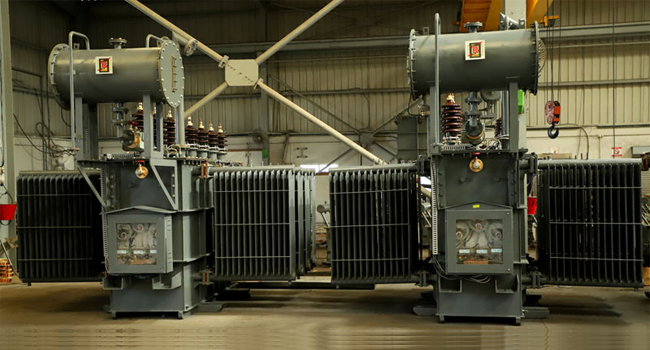

Power Transformer

Transformer with rating 5MVA and above 33kV voltage class is normally known as Power Transformers and is installed in Substations with various protective devices. The accreditation from the national accreditation board for testing and calibration laboratories (NABL) for the VADODARA (ERDA)test laboratory is in accordance with ISO/IEC 17025:2005 for electrical parameters in line with national and international standards

Certification : ISO9001 : 2008,ISO14001 : 2004,OHSAS18001 : 2007

Request a QuoteC3*

- Lowest ambient temperatures :

- Operation - 500C

- Storage / Transport - 500C (*C2 Thrmal shock test carried out at - 500C)

E3

- Nearly Total condensation or heavy pollution or combination of both

- Abnormal level of humidity up to 95%

- According to new IEC 60076 - 16 Standard

F1

- Transformers subject to a fire hazard :

- Self - extinguishing transformer fire

- Restricted flammability required

- Limited formation of fumes

- Limited contribution with calorific energy to the source of fire

- ≤ 5 pC

- Maximum level f parcial discharges measured during special test according to IEC 60076 - 11 standard

- Resistant

- Safe

- Versatile

- Economic

- Compact

- High Quality & High Power Saving Transformer

Magnetic core

The magnetic core of the transformers is manufactured from a high grade, cold rolled grain oriented silicon steel. The stacking of the laminations is either butt lap or step lap type. The magnetic core is generally of a multi-layer, circular cross section type, where the slitting and cutting of the magnetic core is done by automatic machines. In order to reduce the sound level of the transformer to a minimum, the magnetic core and its framework are carefully sized to minimize the vibrations and in particular, the magnetostriction effects which constitute the main sources of sound in distribution transformers. In addition, in order to reduce the no load losses and / or the no load current ofthe transformer, the quality of the magnetic steel and the induction together with the design of the magnetic core are carefully chosen to meet the requirements.

Surface protection

One of our major quality commitment is to provide high-quality surface protection. The coating (painting) type is chosen in accordance with the environmental conditions, considering the degree of pollution, humidity, etc. Zinc Spray / Hot dip galvanized tank, HV/LV cover and conservator may also be provided.

Tappings

Tap changers allow voltage adjustment for a variation of the supply network voltages on the primary side of the transformer, or for increasing or decreasing the secondary voltage. Tappings are provided on the primary winding and connected to an off-circuit tap changer. The operating handle for the hand-operated, off-circuit tap changer is mounted outside. The standard tapping range is ±2x2.5%. However we can provide tapping range as per customer requirement. For adjustment operations, the transformer needs to be de-energized. However, on request for special applications, an on load tap changer can be provided.

High voltage winding

The high voltage winding material is either copper or aluminum: the choice depends on the load losses and on the rated power. The shape of the conductor is either of a round or rectangular type. To obtain a controlled temperature gradient, cooling ducts are added in the coil. High voltage coils are in long layers or of disc type. Due to recent developments in the winding process, interlayer insulation and wire insulation have allowed the automation of the winding process.

Customer Benefits

- Extreme versatility of the range

- High quality and reliability

- Economically optimized

- Capitalization of the losses

- Easy recycling

- Proven and permanently

- optimized technology

- Reduced dimensions

- Solid construction

- Long life-cycle with low maintenance